Wir möchten Ihnen einige talentierte Menschen vorstellen

„Es sind die Menschen.“ Das ist die Antwort, die Sie am häufigsten bekommen werden, wenn Sie unsere Mitarbeiter fragen, warum sie hier gerne arbeiten. Unser Team gewinnt dank talentierter Menschen, die agiler sind, schneller handeln und mehr Verantwortung übernehmen. Wir motivieren uns gegenseitig, besser zu werden, meistern zusammen Herausforderungen und finden neue und bessere Verfahrensweisen. Wir ermutigen unsere Mitarbeiter dazu, ihren eigenen Erfolg zu gestalten.

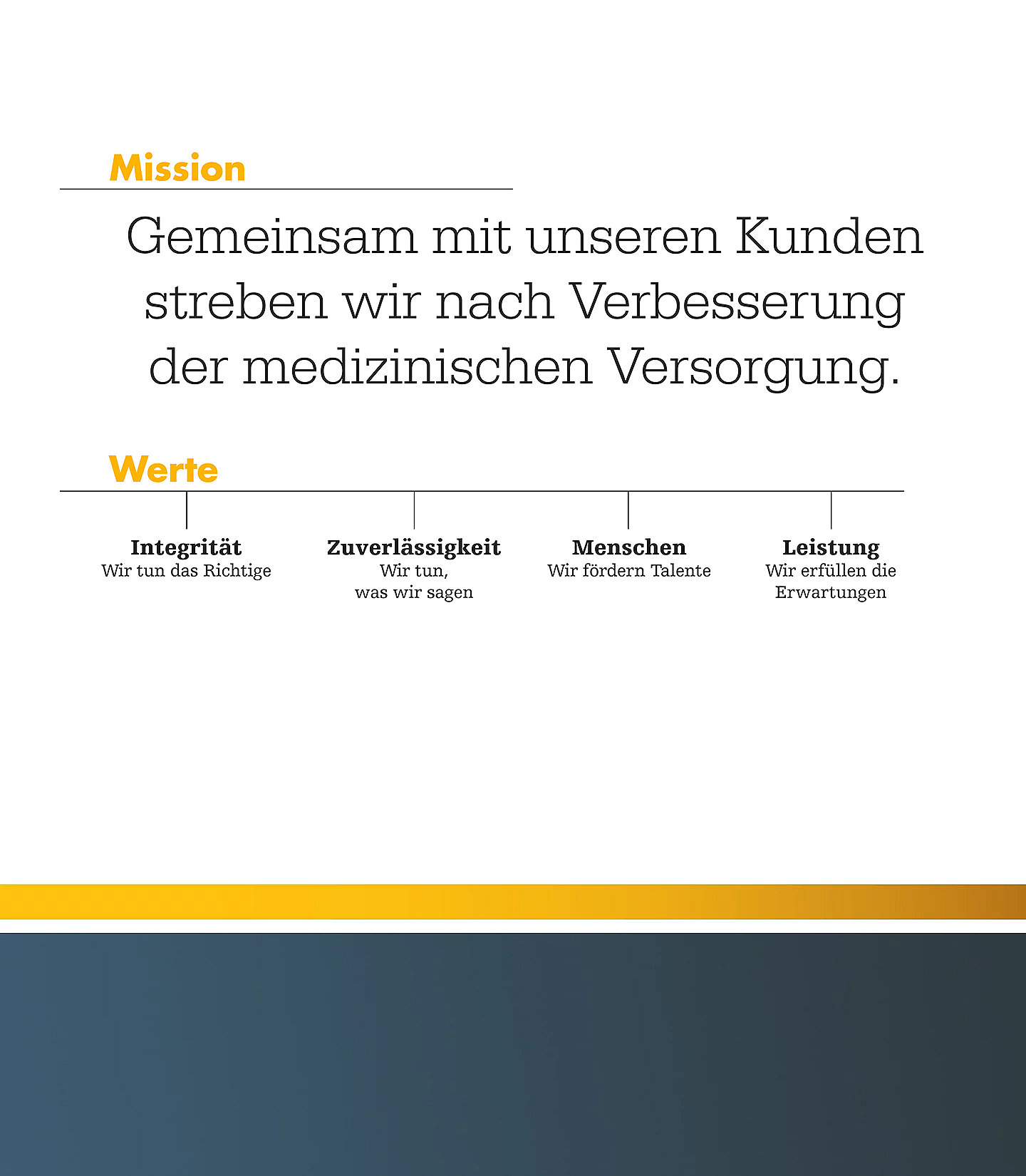

Unternehmensverantwortung

Es gibt zahllose Möglichkeiten, unsere Mission zur Verbesserung der Gesundheitsversorgung zu verfolgen. Wir empfinden auch eine große Verantwortung gegenüber unserer Gesellschaft. Deshalb investieren wir Zeit und Ressourcen in die Bereiche, die unseren Mitarbeitern, Kunden und der Gemeinschaft, in der wir leben und arbeiten, am wichtigsten sind.

Mehr lesen

Mehr lesen

Unsere Geschichte

Immer wenn Dr. Homer Stryker, ein orthopädischer Chirurg aus Kalamazoo, Michigan in den USA, der Meinung war, dass gewisse medizinische Produkte nicht den Anforderungen seiner Patienten entsprachen, erfand er sie einfach neu. Als das Interesse an diesen Produkten immer größer wurde, gründete Dr. Stryker 1941 ein Unternehmen, um sie zu produzieren. Heute sind wir eines der größten Unternehmen für Medizintechnologie weltweit.

Mehr lesen

Mehr lesen

Letzte Meldungen

Fortune ernennt Stryker zum 23. Mal in Folge zu einem der „Most Admired Companies“ der Welt

Stryker wird das siebte Jahr in Folge als einer der World’s Best Workplaces ausgezeichnet

Sehen Sie sich Kevin Lobo, den Vorsitzenden und CEO, zu „Leading With Strengths“ von Gallup an

SYK CORP 2021-10-94_Rev-2